Zero-cost money saving for hot water

When it comes to absolutely zero-cost ways to save energy and money the options are few and far between. Unless you’re routinely leaving your windows open in the winter, it basically comes down to turning things off, lowering your expectations of what’s acceptable in some regard, or increasing the efficiency of your existing systems.

Here I’ve gone for the third option and experimented with increasing the efficiency of my hot water system by adjusting the timings of my boiler. The idea is that by reducing how often the boiler heats the water I can get both a higher efficiency from the boiler and a decreased heat loss from the cylinder. If I can pull this off, it should give me both money and carbon savings with no downsides.

How much energy do we use for hot water right now?

We currently have a hot water cylinder that’s heated by a gas-fired boiler. I already know that hot water accounts for about 10% of my gas usage, or around 1,050 kWh/year.

Our hot water cylinder is 210 L in volume which is quite large for our household. We program the boiler to fire up for an hour each day to heat this cylinder. This is a very typical approach for people with cylinders like us.

Importantly, the boiler doesn’t run flat out for that hour. In fact, it only needs to run for a small fraction of the hour to meet our daily demand.

To illustrate, if our incoming water in the winter is 5°C and our target temperature is 60°C, then it would only take 13.5 kWh to raise that whole tank of 210 L to the target temperature:

Energy (J) = mass (kg) * specific heat capacity (J/(kg⋅°C) * change in temperature (°C)

Energy = 210 kg water * 4.2 kJ/(kg⋅°C) * (60-5)°C = 48.1 MJ

Energy (J) / 3.6 MJ/kWh = power (kW)

48.1 MJ / 3.6 MJ/kWh = 13.5 kWh

Our 18 kW boiler could provide 13.5 kWh in about 45 minutes, flat out.

Of course, normally we don’t use the full cylinder in a day and we’re not always in the middle of winter which means that we’re only running for a fraction of that 45-minute period anyway.

Where is there saving to be made?

The savings can be made in two different places, both of which revolve around the fact that a cylinder not 100% full of hot water is more economical than one filled entirely with hot water.

Savings through reducing heat loss

For the first place to make savings, we need to know that any hot object loses heat to its cooler surroundings. To minimise this, our cylinder has 50 mm of factory-applied spray foam on it, but even the best insulation doesn’t completely prevent heat loss.

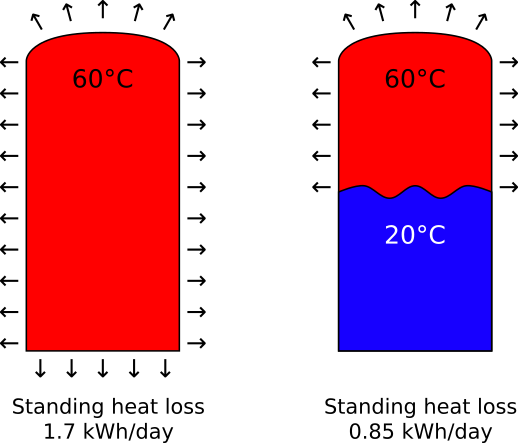

The amount of heat lost from a hot object is proportional to both the temperature difference (i.e. the inside temperature of the cylinder minus the surrounding room temperature) and the area of the object, with larger objects losing more heat.

We can exploit this because the way that hot water cylinders work is that they are designed to keep water “stratified”. This means that cooler water enters at the bottom and remains in a layer there while hot water is drawn off at the top, also remaining in a layer ready for use.

If a cylinder is half full with hot water and half full with cold, then the heat loss is also halved (Figure 1).

If I can get away with allowing a cold layer to build up over a couple of days at the bottom of the cylinder, then I will reduce overall heat loss.

Savings through increased boiler efficiency

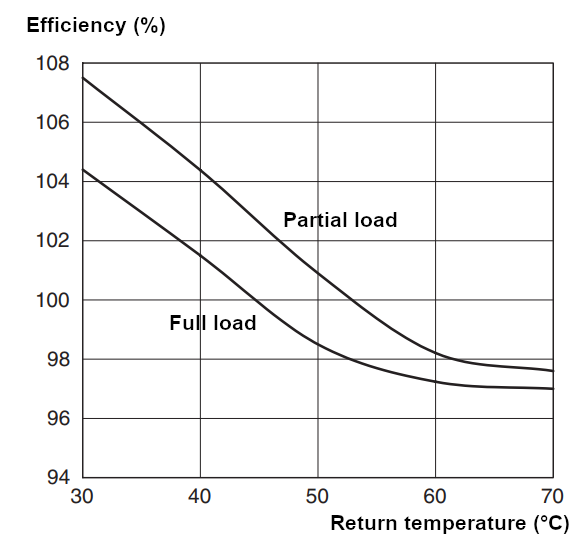

The second place to make savings comes in when we do reheat the water. All gas boilers have a published efficiency ratings. For mine, this is 89.7% according to the old 2009 SEDBUK rating system1.

The SEDBUK efficiency is an average rating and means that over a typical year, my boiler will be about 89.7% efficient at turning the heat from burned gas into useful heat in the house. The remaining 10.3% will be lost through the exhaust.

Importantly though, the SEDBUK rating is just an average. It will be too high at some points and too low at others. More accurately, boiler efficiency should be expressed on a graph, like Figure 2 (adapted from here Cockroft 20072).

Now you can see that boiler efficiency can vary from a low of below 87% to a high of almost 98%, depending on the load and the flow temperature.

Because I’m now storing more cold water in the base of the cylinder, I’m also lowering the return water temperature to the boiler. In turn, this will get me a few more percent of efficiency out of the system. It’s not as big an effect as the heat loss factor, but it’s still a contribution to savings.

How much are the savings?

There’s only one way to find out if this is a meaningful money-saving venture – adjust the boiler to fire every other day instead of every day and measure gas usage.

I did this as part of my efforts to work out how my gas usage broke down. I ended up using a pattern of firing on Monday, Wednesday, and Friday because of limitations with my seven-day timer.

The results were so striking I knew very quickly that there were significant savings to be made.

My baseline gas usage was recorded as 5.3 kWh/day, just for hot water (i.e. excluding any contribution from cooking. My heating was already off). Over a nine-day period in the late spring of 2022, I switched to alternate-day boiler firing and used only 3.5 kWh/day for hot water, a 34% reduction from normal usage.

At the time of writing this I’m paying about £0.12/kWh for gas. This is much higher than recent prices, driven by current geopolitical instabilities in Europe, but at this price I can expect to save about £80/year on my hot water bill.

For days when the boiler did fire, I used about 150% of a typical day’s gas usage. This makes sense as I’m having to heat a larger volume of water compared to heating every day.

Sanity check - is this too good to be true?

A 34% saving seemed quite large - unexpectedly so in fact. It didn’t seem possible to save this much from just a simple timing change so I thought I’d run a quick sanity check on the figures.

A first approximation is to assume that all the savings are coming from the reduced heat loss from the cylinder – something that arises because a cylinder only half-full with hot water loses heat at only half the rate of a full cylinder.

In this case, heat loss from the cylinder can be estimated as shown here, assuming I use about one third of the full cylinder of water a day:

Has this been the 100% friction-free money-saving I thought it might be? Not completely. On the odd day, especially when we do a ton of laundry for example, we’ve found that the hot water becomes decidedly cool for the morning shower. This is really only a problem with the 3-day gap that arises with our 7-day timer though. Someone who could programme a true “every-other-day” heating schedule wouldn’t have this problem.

Conclusions

Overall, I’m convinced enough that I’m making real savings on my hot water bill that I’ve left the boiler timing on the alternate days setup.

Has this been 100% friction-free money-saving? Not quite. On the odd day, especially when we do a ton of laundry for example, we’ve found that the hot water becomes decidedly cool for the morning shower. This is really only a problem with the 3-day gap that arises with our 7-day timer though. Someone who could programme a true “every-other-day” heating schedule wouldn’t have this problem.

That being said, this is real saving and as close to zero-impact as I could have hoped.

-

The SEDBUK rating has now been replaced by Energy related Products (ErP) directive, but is still applicable for considering the efficiency of older appliances. ↩︎

-

https://www.esru.strath.ac.uk//Documents/07/BRE_E302_040707.pdf ↩︎

Posts in this Series

- Zero-cost money saving for hot water

- Planes, Trains, and Automobiles

- Breaking down household natural gas use

- Carbon footprint of my household gas and electricity use

- How big is my household carbon footprint?